Overview

The OCCP, in which Aspire holds a 100% interest, is based upon extraction of high quality ‘fat’ coking coal from mining license MV-017098, which is situated in Tsetserleg soum (district) of Khuvsgul aimag (province) in northwestern Mongolia.

Key Facts

| Ovoot Coking Coal Project | |

| Ownership | Aspire has a 100% interest in Ovoot |

| Status | Under Development |

| Expected product | Premium ‘fat’ coking coal |

| Targeted construction start | Q2 2025 |

| Targeted production start | Q4 2026 |

| License expiration | August 2042 (extendable twice by 20 year periods) |

| Total JORC Resource | 219.4 Mt |

| Total JORC Reserve | 130.1 Mt |

A Project of Considerable Scale

Coal Resource and Coal Reserve Estimates

The OCCP boasts a significant JORC (2012) compliant Coal Resource and Coal Reserve, with details of the most recent estimates as follows:

Total Coal Resource of 219.4 Mt

After providing supervision of a small-scale infill drilling program conducted within MV-017098 in Q4 2022, SRK Consulting MGL LLC (SRK) prepared an updated estimate of the Coal Resource, evaluating historical and new information gained. A Total Coal Resource of 219.4 M was estimated, including:

- Inferred: 19.0 Mt.

- Measured: 99.5 Mt

- Indicated: 100.9 Mt

All seams and plies identified within MV-017098 were considered in this exercise. To facilitate this estimate, a gridded seam model of the deposit was prepared based on data from 198 boreholes within the license area and 72 boreholes from within the adjacent license area. In total 196 Structure Points of Observation and 104 Quality Points of Observation were used.

Total Run-of-Mine Coal Reserve of 130.1 Mt

Using the Coal Resource model prepared to facilitate the updated Coal Resource estimate as basis, SRK prepared an updated estimate of the Coal Reserve present within MV-017098. This estimate only considered extraction of the Upper Seam within the deposit, to a maximum depth of 350m from surface. Coal below 350m depth, and from the Lower Seam, were excluded from this estimate on basis of high-level assessment that the future extraction of the Lower Seam via underground mining methods arefeasible and preferable.

The Life-of-Mine plan prepared as part of the Coal Reserve estimate process outlines a 31-year mine life. Following commissioning mining and processing operations at 1.5 Mtpa Run-of-Mine, the production rate is scheduled to ramp up to 2.5 Mtpa before increasing to 5.0 Mtpa following modular expansion of the Coal Handling and Preparation Plant (CHPP). The production ramp-up is deliberately conservative, and opportunities to accelerate this will be pursued. A Total Coal Reserve of 130.1 Mt of Run-of-Mine (ROM) coal was estimated, including:

- Proved: 76.8 Mt

- Probable: 53.3 Mt

Infrastructure & Logistics

World class infrastructure is planned to enable processing of coal mined onsite to produce a value-added washed ‘fat’ coking coal product and facilitate efficient transloading between road trucks and rail wagons at the planned Erdenet Rail Terminal (ERT). A global tender process has been conducted for the design, supply, procurement and construction of this infrastructure and a contract for the combined works is expected to be entered into soon, with construction activities to commence within 2025 and scheduled for completion in Q4 2026.

The CHPP has been carefully designed to minimise raw water requirements, with inclusion of filter press dewatering of fine coal and fine reject materials. This maximises the amount of water recovered for reuse, and avoids requirement for a tailings dam onsite. Containment of potential dust emissions has also been prioritised, with enclosed conveyor gantries, enclosed crushing and processing equipment, an enclosed product coal stockpile and direct bin to truck loading system which also supports the efficiency of trucking operations.

The infrastructure to be constructed at the ERT has been designed similarly to minimise raw water consumption and ensure containment of potential dust emissions, whilst supporting highly efficient and productive transloading of coal from road trucks to rail wagons. Trucks will unload inside an enclosed building from where coal will be conveyed to an enclosed product coal stockpile, from where it will be reclaimed to a train loadout facility for direct deposition into wagons.

Processing coal mined from the Ovoot deposit onsite will enable production of a more valuable washed ‘fat’ coking coal, of high and consistently quality. Washing coal onsite will also reduce the volume of material needing to be transported to customers, with gangue materials removed prior to trucking and railing. In Mongolia, the process of value-adding to raw mineral products enables a reduction in the mineral royalty rates payable and the ability to reclaim the Value Added Taxes incurred on the Cost of Goods Sold.

Premium ‘Fat’ Coking Coal

Indicative Product Specification

The washed coal from the Ovoot Coking Coal Project is expected to be classified as an ‘FM36 Metabituminous’ coal in accordance with the Chinese national standard GB/T 5751-2009 ‘Chinese classification of coals’. Colloquially this is referred to as a ‘fat’ coking coal.

This classification represents the highest quality of ‘fat’ coking coal in the Chinese classification system. As a premium ‘fat’ coking coal it is highly sought after by coke producers for its unique coking properties. The coal from Ovoot is also considered to be a ‘scarce’ coking coal under Chinese national standard GB/T 26128-2010 ‘Classification and utilization of scarce and special coal resources’, and it should be utilized carefully to improve the resource utilization efficiency of lower quality coals.

Highly Sought-After Product

Demand for Ovoot Product:

Steel is essential to support global sustainable development because it supports the infrastructure, technologies, and innovations required to build a more resilient, inclusive, and environmentally responsible future. Steel is critical for buildings and housing, transportation infrastructure and equipment, and energy infrastructure. Without steel, these foundational elements of a sustainable society couldn’t be built at scale. Steel is necessary for sustainable development because it is a critical enabler of infrastructure, clean energy, economic opportunity, and climate resilience.

Global steel demand is forecast to increase due to a combination of economic development, urbanization, population growth, and the global push toward decarbonization and sustainable infrastructure. In the medium term, blast furnace capacity must expand to ensure the world has enough steel to support economic growth, infrastructure development, and the energy transition. While green steel presents a plausible long-term solution, its current scale, cost, and supply constraints mean that traditional steelmaking (augmented by emission-reduction technologies) will remain critical for the foreseeable future. Consequently, demand for high-quality coking coal is also expected to continue to rise.

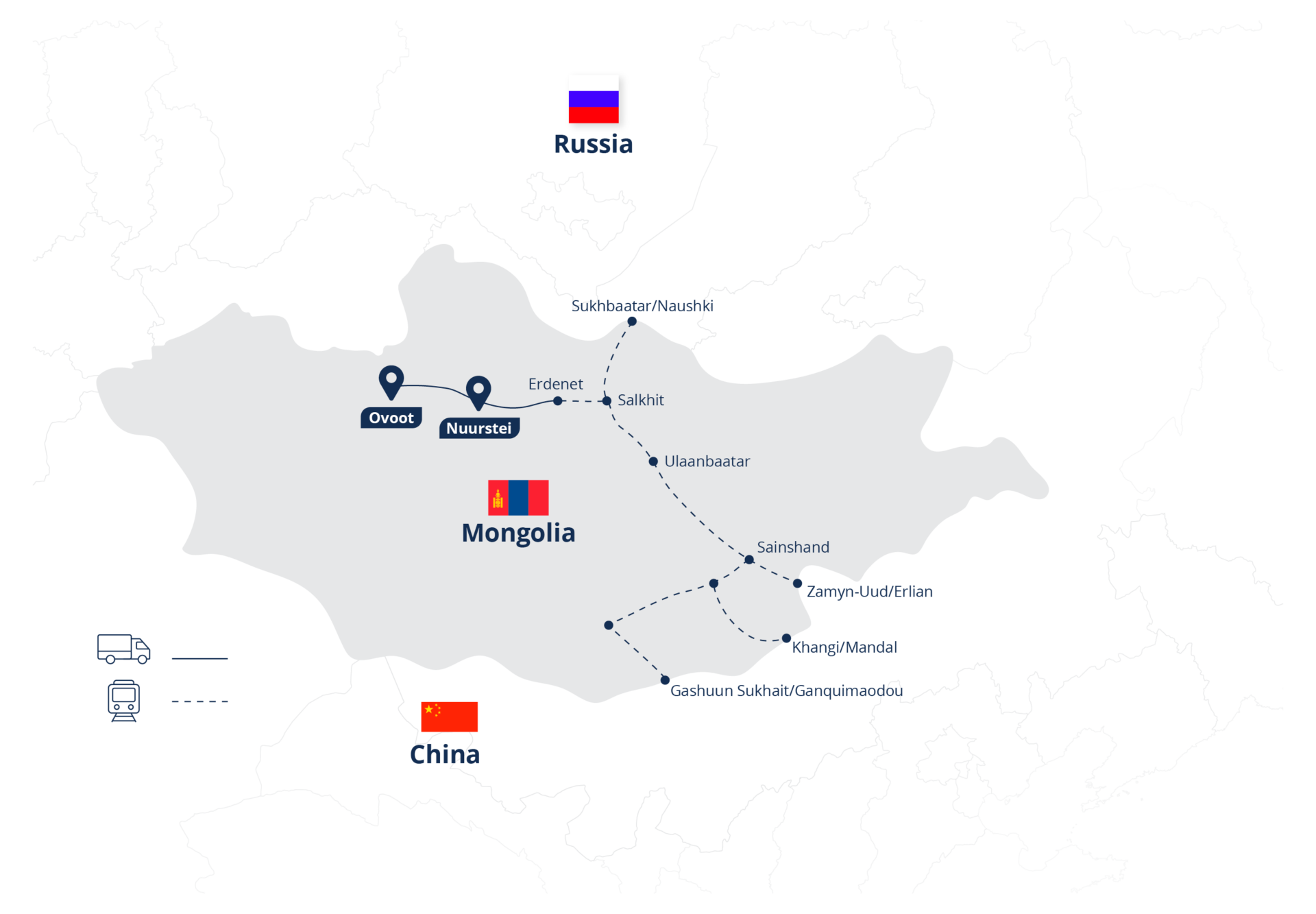

Strategically Located Proximal to End Markets

China has accounted for over 50% of global annual steel production since 2013. Being adjacent to Mongolia it is a prime target for distribution of the high quality ‘fat’ coking coal from Ovoot. Market analysis prepared for Aspire by Fenwei Digital Information Technology Co., Ltd. (Fenwei) focused on Target Market Regions in the northern and northeastern Chinese provinces of Inner Mongolia, Hebei, Liaoning, Heilongjiang and Jilin.

This study concluded that in 2024, there was a local supply deficit of ‘fat’ coking coal of approximately 16.4 Mt, and that this was forecast to increase to 18.1 Mtpa by 2029. Ovoot is strategically positioned to meet this significant market demand in northern and northeastern China, with existing rail connections providing access to multiple potential ports of entry into China.

To access the in-place rail network, approximately 190 km of new paved highway will be constructed between the Ovoot mining license and Murun, the administrative centre of Khuvsgul aimag, connecting to the existing national highway network. Coal will be transported across this highway network to a bespoke transloading facility to the planned Erdenet Rail Terminal (ERT), where it will be transloaded from road trucks to rail wagons able to access the Trans-Mongolian Railway. This road development will not only support the efficiency of coal transportation, it will benefit the local communities through establishment and improvement to public road infrastructure. The construction will align with Mongolian standards for inter-city highways and it will be built and operated with environmental considerations in mind, including the use of low-emission, fuel-efficient vehicles compliant with local safety rules applicable to public road use.

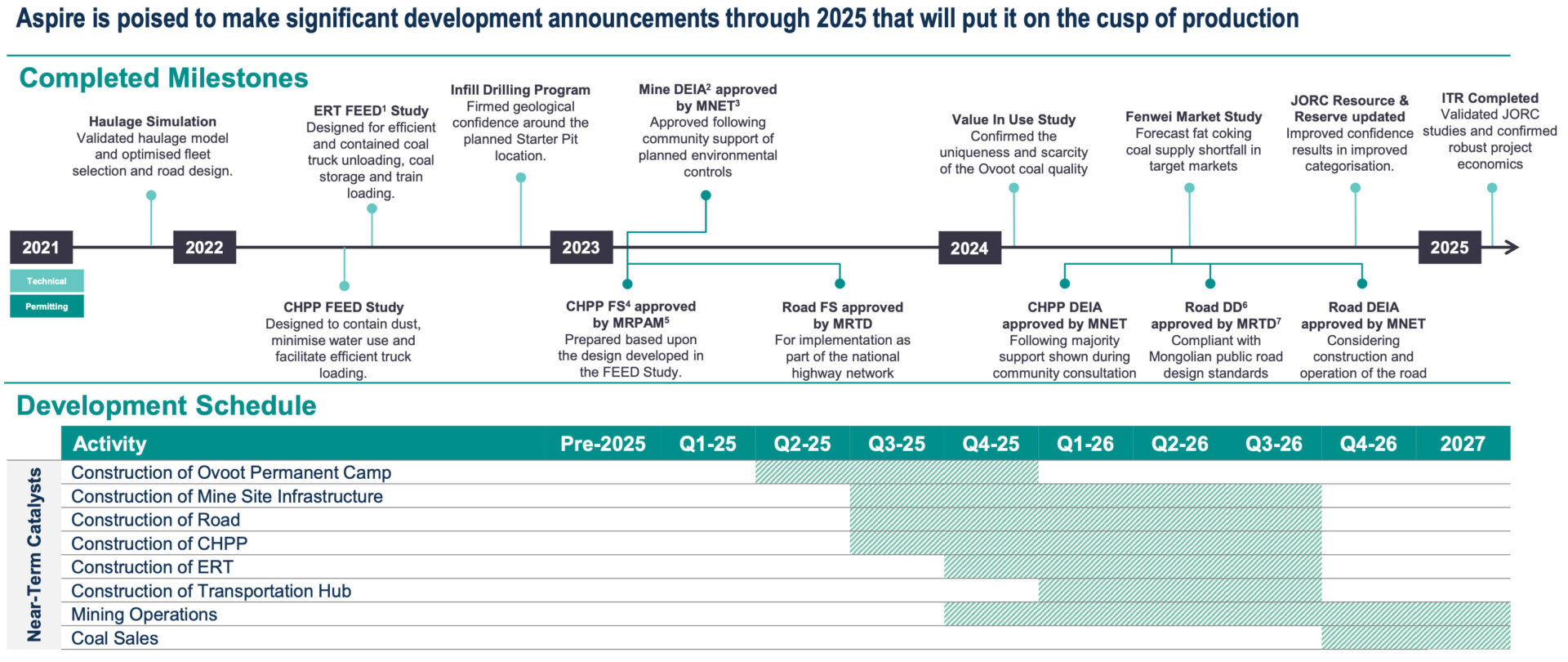

Pathway to Production

Progress and Future Plans

Aspire has made significant progress in securing the regulatory approvals and permits necessary to commence construction of the Ovoot Coking Coal Project. The Company remains on track to begin construction in 2025, with coal production and sales projected to commence before the end of 2026. This project is set to deliver low-cost premium coking coal production from one of the world’s most promising coking coal deposits.

Near-term, low-cost premium coking coal production from the world class Ovoot Coking Coal Project in Mongolia